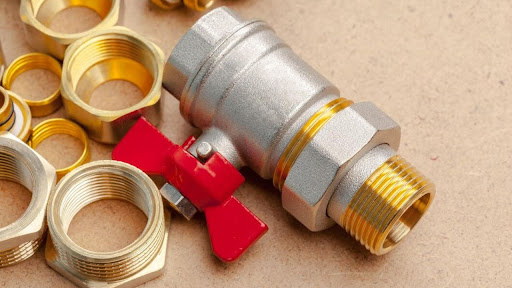

In fluid transfer and piping systems, efficiency, reliability, and ease of use are paramount.

Enter camlock fittings – versatile, robust, and time-tested components that have revolutionized fluid handling across a multitude of industries.

They represent a cornerstone in the evolution of fluid handling technologies, providing a reliable means of connecting and disconnecting pipelines swiftly and securely.

From their ability to streamline operations and ensure leak-free performance to their versatility across a spectrum of industries, we delve deep into the reasons behind the widespread adoption of these fittings.

1. Rapid Connection and Disconnection

One of the most significant advantages of these components is their unparalleled speed and ease of connection.

Featuring a simple yet ingenious design, these fittings enable operators to quickly secure connections without the need for specialized tools or equipment.

The cam arms, which give the fittings their name, can be effortlessly engaged or disengaged, allowing for swift assembly and disassembly.

This rapid connection capability translates into significant time savings, particularly in applications where frequent coupling and uncoupling are required.

2. Versatility Across Multiple Applications

Renowned for their versatility, they cater to a wide range of fluid transfer applications across various industries.

Whether it’s in agriculture, manufacturing, petroleum, chemicals, or food and beverage processing, these fittings excel in providing reliable connections for liquids, gases, powders, and granular materials.

Their compatibility with different media, coupled with various material options such as stainless steel, brass, aluminum, and polypropylene, makes them suitable for diverse operating conditions and environments.

3. Leak-Free Performance

In fluid handling systems, preventing leaks is paramount to ensure operational efficiency and safety.

These fittings offer exceptional leak-free performance, thanks to their robust construction and secure locking mechanism.

When properly engaged, the cam arms create a tight seal between the fitting and the mating surface, effectively preventing leakage even under high-pressure conditions.

This reliability in sealing minimizes the risk of product loss, contamination, and environmental hazards, enhancing overall system integrity.

4. Durability and Longevity

Quality construction contributes to their durability and longevity in demanding industrial settings.

Whether subjected to corrosive chemicals, abrasive materials, extreme temperatures, or high pressures, these fittings are engineered to withstand the rigors of the toughest operating conditions.

Materials such as stainless steel and aluminum offer excellent resistance to corrosion and wear, ensuring prolonged service life and minimal maintenance requirements.

As a result, investments in these quality components yield long-term benefits in terms of reliability, uptime, and cost-effectiveness.

5. Interchangeability and Compatibility

Another advantage is their interchangeability and compatibility with existing systems and equipment.

These fittings adhere to standardized specifications such as those outlined by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), ensuring uniformity and interoperability across different manufacturers and suppliers.

This standardization simplifies procurement, installation, and maintenance processes, as operators can easily source compatible fittings and components from various sources with confidence.

6. Safety and Ease of Use

Safety is paramount in industrial operations, and these are designed with user safety in mind.

The intuitive design and foolproof operation minimize the risk of human error during connection and disconnection, reducing the likelihood of accidents and injuries.

Additionally, the secure locking mechanism ensures that fittings remain firmly in place during operation, preventing unintended disconnections that could lead to spills, leaks, or equipment damage.

By prioritizing safety and ease of use, the fittings contribute to a safer working environment and peace of mind for operators.

7. Cost-Effectiveness and Return on Investment

While the initial cost of camlock fittings may vary depending on factors such as material, size, and manufacturer, their long-term cost-effectiveness is undeniable.

The rapid connection and disconnection capabilities translate into significant time savings during installation, maintenance, and system reconfiguration.

This efficiency not only reduces labor costs but also minimizes downtime, allowing operations to resume swiftly without prolonged interruptions.

Conclusion

Camlock fittings represent a cornerstone of efficient fluid handling systems, offering a plethora of advantages that enhance productivity, reliability, and safety.

From their rapid connection capabilities and versatility across applications to their leak-free performance, durability, and ease of use, the fittings continue to be the fitting of choice for professionals across diverse industries.

As the demands for efficiency and performance in fluid transfer operations persist, these remain indispensable components that unlock a world of possibilities for seamless and reliable fluid handling.